Detecting Evaporative Cooler Water Leaks

When evaporative coolers leak, damage and downtime ranges from poor performance, increased electricity use, and unsightly staining on walls or ceilings; to unit failure, sick building syndrome, and structural damage due to long-standing escape of water.

Discover why evaporative coolers leak, and key attributes of effective water leak detection solutions that mitigate damage and downtime.

What causes evaporative coolers to leak water?

1. Incorrect or improper installation

-

Evaporative coolers require a flat, level surface to operate properly. If installed on a surface that isn't flat and level (or if affected by excessive vibration), water is unlikely to drain properly, instead pooling and leaking from the unit.

2. Challenging environmental conditions

-

Evaporative coolers operate less efficiently in high-humidity areas. This causes them to release excess water as they struggle to cool the air, which often leads to leaks.

3. Operational wear and tear missed by maintenance

Evaporative coolers require more maintenance than other HVAC systems, which is a challenge for time-poor facilities management teams.

Missing scheduled inspections and maintenance has a direct impact on the likelihood of water leaks:

-

The water lines that deliver water to the cooling pads can become clogged or cracked over time, leading to water overspill and leaks.

-

As the cooling pads absorb water, they may become clogged with minerals, degrade, and become damaged. This frequently leads to water being improperly distributed throughout the unit, resulting in water leaks.

-

The pan or tray holding water inside the cooler can also develop cracks or rust over time, leading to water leakage.

What happens when an evaporative cooler leaks?

Water escapes

-

Water leaking from from the evaporative cooler pools on the surface underneath it.

-

The water available for the evaporative process is reduced, lowering the cooler’s efficiency and its ability to cool effectively.

- People may begin to notice the lack of cooling, and turn the temperature down in order to achieve the desired effect.

Damage occurs

-

Whatever water doesn't pool on a non-absorbent surface immediately below the evaporative cooler will either be absorbed into the horizontal surface, or travel downwards, through to the space below. Mold and mildew will begin to form, and a smell may start to develop.

-

Components of the evaporative cooler such as the water tray, pump, and pads may start to degrade, rust, or corrode.

-

Cooling performance will continue to be affected, and tenants are likely to notice both the poor performance, and the increased electricity bills.

Damage escalates

As damage escalates, so will downtime:

-

Mold and mildew will grow unchecked in damp areas, affecting air quality and thus tenant and/ or employee health. "Sick building syndrome" may be diagnosed in more severe instances, requiring tenants to cease occupation until cleanup has been completed.

-

Large or longer-running leaks may have a negative impact on structural elements of the building, requiring more comprehensive repairs.

-

The evaporative cooler units may stop working entirely and require extensive recommissioning or replacement. Areas that rely on the units for cooling may force a partial or complete shutdown until they can be replaced. Such unplanned downtime - whether days or months - will likely cause further commercial impact such as loss of productivity.

Evaporative cooler water leaks are poorly served by traditional water leak detectors

Detecting water leaks from evaporative coolers in commercial & industrial building infrastructure

-

Manual inspection is the most common method of water leak detection - but not the most reliable. Facilities teams who are pressed for time may be unable to complete maintenance as scheduled. And those same time pressures, plus human error, mean that leaks are easily missed.

-

Puck sensors only offer coverage for a very limited area, meaning a significant volume of water must be pooled in the right spot for a leak to be detected.

-

Rope sensors are considered less reliable due to their high false positive rates - many experienced facilities teams distrust leak alerts when dust, or a single drop of moisture can trigger them.

-

Flow meters are great at detecting substantial difference in pressure, but tend to overlook smaller leaks, and are unable to pinpoint exactly where in the network the water is pooling.

Effective water leak detection for evaporative coolers requires comprehensive capabilities

-

To provide accurate information on the leak and its location, so that facilities managers can prioritize investigation and repair according to urgency, potential damage, and the impact of any necessary downtime.

-

To avoid reporting false positives, while also being able to detect a leak early enough to avoid significant damage and downtime being caused.

-

Fast, simple installation that doesn't overburden already-stretched facilities teams.

-

Low or no maintenance requirements once installation is complete, particularly when in inaccessible locations.

-

To provide aggregated data to facilitate improved decision-making across facilities.

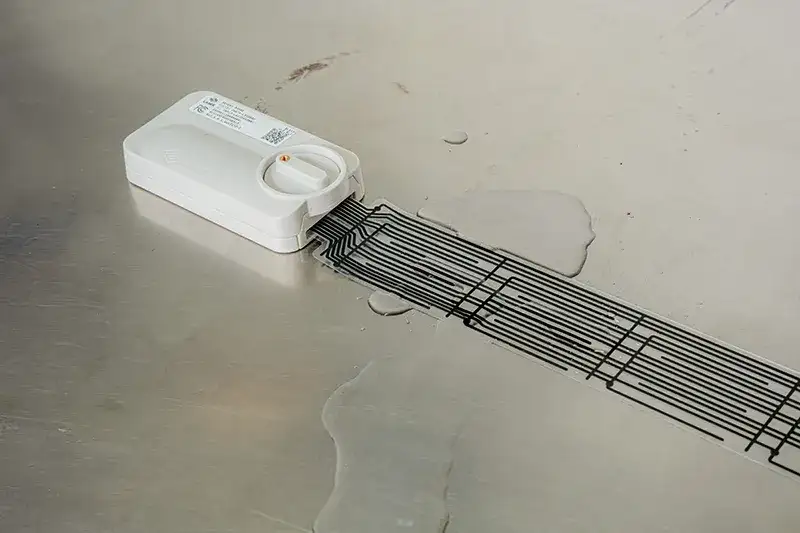

How LAIIER’s Severn WLD detects water leaks from evaporative coolers

Severn WLD™ automatically monitors and detects water leaks from evaporative coolers in commercial and industrial settings

- Building and facilities managers automatically receive emergency leak alerts, clearly identifying the specific evaporative cooling unit and location where water is pooling. Further data can be reviewed to determine leak size and growth, making it easier to prioritize repairs.

- Quick, tool-free, self-adhesive installation minimizes setup effort. Its robustness and IP65 rating make it suitable for use in even in more rugged environments.

- Each device remains in place until you decide to move it. With a 6-year battery life, devices are maintenance-free, even after a leak occurs.

- Water leaks can be reliably detected in the early stages, without requiring manual inspections, or visible signs of damage.

- The same water leak detection device can serve multiple use cases, both in buildings and in industrial applications.

Explore the benefits of early water leak detection

Book a call with our team for a confidential discussion about detecting water leaks from evaporative coolers.