Detecting Flange Water Leaks

When flanges leak in commercial and industrial settings, the damage and downtime can be anything from a minor inconvenience for tenants, to a significant event that shuts down processing and production lines for an extended period.

Discover why flanges are common sources of water leaks, the damage that's caused, and key attributes of water leak solutions that offer effective detection for flange leaks.

What causes flanges to leak water?

There are 2 main causes of flange water leaks

1. Incorrect or improper installation

-

Over-manipulation of the pipes being joined by a flange can cause water leaks. Using excessive force, pipes with inadequate flexibility, and/ or a lack or improper location of pipe supports and restraints, all place excessive load on the flanges, which are then prone to fail.

-

Choosing the correct gasket and installing it correctly is important. Select the wrong material, and it will corrode or blow, causing water to leak. Off-center installation creates uneven compression, and makes the joint prone to leaks.

-

Misaligned flanges will cause uneven gasket compression and local crushing, both of which often result in water leaks.

-

Inconsistent bolt tightness leads to crushed gaskets, permitting escape of water. This is particularly a concern in high-heat applications, when heavily loaded bolts relax due to the heat.

2. Challenging environmental conditions

-

Temperature variations can cause thermal shock in flanges. In high temperature applications, this can result in flanges temporarily deforming, enabling escape of water.

-

Temperature variation around the circumference of the flange may also induce thermal shock.

-

Significant vibration levels can loosen bolts over time, causing the flanges to loosen, and ultimately allowing the escape of water from the pipes.

Where do flange leaks occur?

Water leaks from flanges can occur wherever they are used on pipework.

In building infrastructure

Flanges are a significant risk factor for water leaks within a commercial or industrial building's infrastructure, with water pipes typically running behind walls, above ceilings, and under floors. Flanges are commonly used to join water risers, as well as pipework related to water heaters, HVAC, and appliances.

Flanges that present the greatest risk of downtime and damage tend to be located on higher-pressure water pipes with larger diameters, and those subject to greater thermal stress and vibrations.

Because there is an aesthetic preference for concealed pipework, leaking flanges within the building's pipe network can be difficult to detect until visible damage is done.

In industrial settings

The sheer volume of flanges present in industrial settings mean that the risk of water leaks is significant: nearly every manufacturing facility or plant has thousands of flanges in place.

While variations occur depending on what is being processed or manufactured, higher temperatures and greater vibration levels are typically anticipated in industrial settings, leading to increased risk of thermal shock and loosened flange bolts.

While pipework is often visible, its complexity and sheer scale mean that water leaks can go undetected for some time. In many cases, health and safety considerations necessitate partial or complete shutdown to facilitate manual inspection for water leaks. And even if it is scheduled, such downtime is a significant expense.

What happens when a flange leaks?

Water escapes

Depending on the pipe diameter, water pressure, and nature of the damage, any of the following scenarios are possible:

- A flange on a branch riser that has a gasket made of the wrong material results in corrosion, and begins to drip in a concealed location within walls. Water runs down vertical surfaces, pools on flat surfaces like floors.

- Grey water pipes with insufficient supports puts pressure the flange, which fails. Grey water escapes in a steady stream, travelling down pipes with some force. It splashes onto vertical surfaces like drywall and insulation, pools on floors, and is slowly absorbed.

- High-pressure water pipes in a processing plant are subject to high levels of vibration and significant temperature fluctuations. The flange bolts loosen, the gasket is crushed, and water escapes in a gush, spraying above, to the side of, and below the affected pipes.

Damage occurs

As the water escapes:

- Whatever doesn't pool on a non-absorbent surface immediately below the failed flange will either be absorbed into the horizontal surface, or travel downwards, through to the space below.

- Porous materials like drywall, wood, and fiberglass insulation will soak water the water up, potentially affecting their integrity.

- Visible staining may appear.

- Water will pool on hard non-absorbent surfaces, creating potential health and safety risks.

- In industrial settings, machinery or technical equipment may be splashed or made wet, impacting safe operating procedures and production processes.

- In extreme cases, flooding will occur.

Damage escalates

As damage escalates, so will downtime:

- Damp areas that don't dry out may grow mold and mildew, affecting air quality and thus tenant and/ or employee health.

- Large or recurring leaks may negatively impact the structural integrity of the building.

- Leaks that impact machinery or equipment may force a partial or complete shutdown in order to facilitate repairs and replace damage equipment. This unplanned downtime - whether days or months - will likely impact planned production schedules and revenue.

Flange water leaks are poorly served by traditional water leak detectors

Detecting flange leaks in commercial & industrial building infrastructure

-

Manual inspection is a time-consuming and expensive way to detect water leaks. A combination of human error and concealed pipework means leaks are easily missed.

-

Puck sensors offer very limited coverage area, so they're best at detecting leaks where a significant volume of water has already pooled.

-

Rope sensors have high false positive rates that make them unreliable - dust, or a single drop of moisture can cause them to send alerts.

-

Flow meters are slow to detect anomalies, may overlook smaller leaks, and can't pinpoint where in the network the water is pooling.

Detecting flange leaks in industrial process and manufacturing environments

-

Manual inspection is labor-intensive, and limited to accessible areas, with a partial or complete shutdown often required to safely perform these. Given the often-vast scale, small leaks are easily missed.

-

Hydrostatic testing creates unnecessary downtime, requiring a complete shutdown in order to fill and pressurize the system with water. It also typically requires visual inspection of flanges to identify any leaks present, driving up the overall cost of detection.

-

Ultrasonic testing, while required by many standardized inspections, only occurs periodically. It's excellent for detecting weaknesses that are potential future leak points, but doesn't actually detect water leaks.

-

Acoustic emission and monitoring have difficulty getting clear results in noisy environments like process plants, and results require significant interpretation.

-

Puck and rope sensors are not only prone to high false positive rates, but are often unsuitable to harsher industrial environments due to their materials and form factor.

To successfully detect water leaks from flanges, a water leak detection solution needs comprehensive capabilities

-

To provide facilities managers with accurate information on the leak and its location, so that they can prioritize its repair according to urgency and potential damage, as well as to the impact of any necessary downtime.

-

To be able to detect a leak early enough to avoid significant downtime and damage, without causing false positives.

-

To provide aggregated data to facilitate improved decision-making across facilities.

-

To be quick to install in order to minimize any shutdown required; and to be robust enough to withstand harsher environments.

- To not require maintenance once installed, particularly when in inaccessible locations.

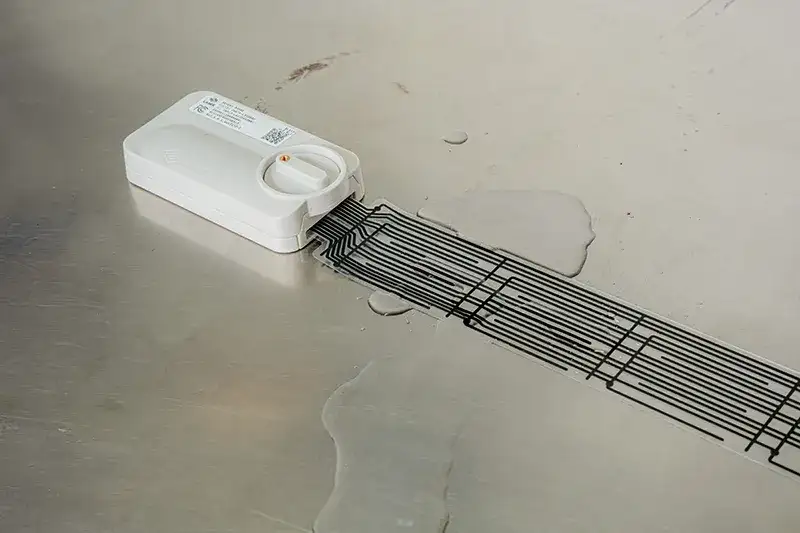

How LAIIER’s Severn WLD detects water leaks from flanges

Severn WLD™ detects leaks throughout water infrastructure in commercial and industrial settings

- Plant and facilities managers automatically receive emergency leak alerts, clearly identifying the specific location where water is pooling. Further data can be reviewed to determine leak size and growth, making it easier to prioritize repairs.

- Quick, tool-free, self-adhesive installation minimizes potential downtime. Its robustness and IP65 rating make it suitable for use in even in rugged industrial environments.

- Each device remains in place until you decide to move it. With a 6-year battery life, devices are maintenance-free, even after a leak occurs.

- Water leaks can be reliably detected in the early stages, without requiring manual inspections, or visible signs of damage.

- The same water leak detection device can serve multiple use cases, both in buildings and in industrial applications.

Explore the benefits of early water leak detection

Book a call with our team for a confidential discussion about detecting water leaks from flanges.